So I got a good understanding of what worked and doesn’t work using GSXR TB’s. The first iteration was with the 04-05 gixxer 600 TB’s (38mm) on modified type 4 fuel injection runners. The design was flawed, but I still managed to make 35-40mpg on a recent trip! The manifold design looked good on paper, but reality is cruel mistress and I had numerous problems sealing them to the TB’s and it didn’t take a lot to pop them off the mani’s. The also had way to short intake length. So back to the proverbial drawing board.

Version 2:

- 06-07 GSXR 600 throttle bodies (40mm)

- 03-04 GSXR 1000 #24 injectors

- custom fuel rails, I made them 🙂

- custom pulley (my buddy Devin on STF made it, it’s sexy)

- idle set screw from a 00-03 gsxr 600 TB (I just happen to have it laying around)

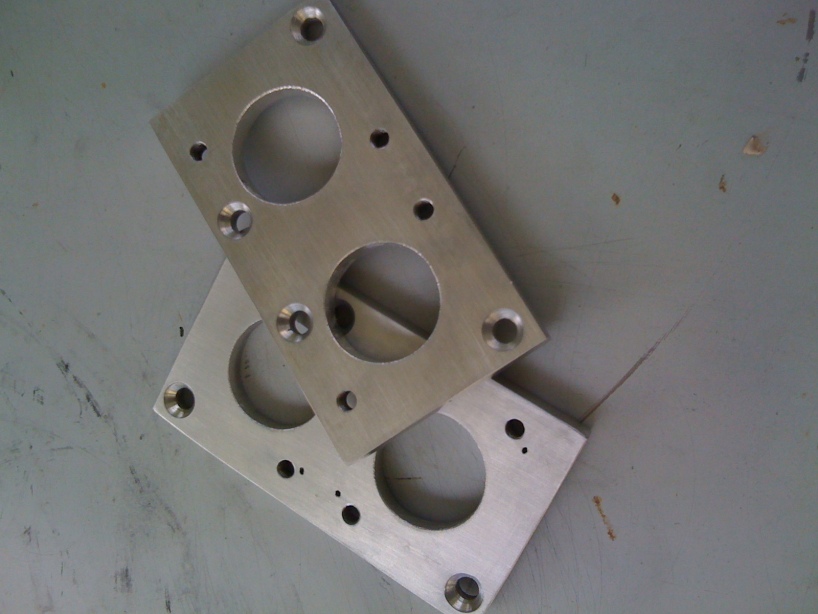

- custom bolt plates between TB’s and IDF manifolds (one of the guys in the club made them on his CNC plasma cutter)

- Spigot flanges (4), mates the TB’s to the bolt plate… KHS-004

- modified Weber DCOE 45 velocity stacks (4), silicone couples and bolt clamps

- fuel system is now all -6an, Performance Products FPR, black fittings, and black braided lines…sexy

- reused my cable linkage, but made a new custom bracket for the right TB

- some porting of the IDF mani’s and bolt plates

Sounds like a lot going on, but it was about a full days worth of work and it was for the most part all bolt together. The big improvement on the design is use of the spigot flanges and bolt plates. I get a real solid mount for the TB’s and it is fairly straightforward to mount to IDF manifolds, which also makes this setup universal for all the ACVW platforms both type 1 and type 4 engines.

Throttle bodies:

I am using the 06-07 TB’s which are basically a similar design to the 04-05 TB’s just a little bigger. They also have 8 injectors instead of 4, so I had to plug 4 extra holes and I removed the extra rail mounts. There is still the extra holes to fill for the servo choke plates. The 04-05 TB’s use a progressive oblong pulley and the 06-07 TB’s use a round pulley. Devastator on shoptalkforums CNC machined me a very nice round pulley. I “modified”, AKA chop sawed the return spring bracket behind the pulley. That was one issue I didn’t get right on the 04-05 TB’s and had to use a extra spring. No extra sping on this version. I also didn’t like idle set screw I used on the first version. This time around I set screw from a junk 00-03 TB that I pillaged a pulley from. I had to get a oddball 5mm x .5 tap, mcmaster-carr to the rescue. That turned out awesome, it looks completely factory…nice!

Bolt plates:

The big problem is the 75mm center to center of the gsxr 600 TB’s and 90mm center to center of the IDF mani’s. The bolt plates are 3/8″ so there is room to do some porting. I only did a light porting to smooth the transition. There is still plenty of meat on the mani’s if I want to try and make a straight shot for the air. I’m trying to create some turbulence to see if I can get better atomization and vacuum. Seems to be working, I have more vacuum at idle and in cruise, but WOT I’m seeing atmosphere. I also make some paper gaskets for between the heads and mani, and bolt plates and manifolds. I went with a fancy hardware choice to mate everything up too. I used SS flat head cap socket bolts for the bolt plates, and metric flanged button heads for the spigot flanges. All are 8mm x 1.25, that’s the same size and pitch as the original studs on IDF mani’s.

Rails:

I could have just modified the metal rails that are stock on the 06-07 TB’s and used the original injectors but I have a set of gixxer 1000 injectors that I have been wanting to run. The 04-05 and 06-07 TB’s use injectors with 11mm inlets. the 03-04 1000 injectors and most cars use 14mm inlets so now I have a lot more injector options. Also the 600 injectors are #18 and the 1000’s are #24, I have been wanting to try out e85, I now have plenty of inj overhead to mess with ethanol. The rails are extruded aluminum from RMR, I got it from their ebay store. It was $5 a foot because it was supposedly damaged, even though it looks fine to me. I used this to machine the rails for the inj http://www.rossmachineracing.com/injectortool.html a bit pricey but it does a fine job. The plan was to use -6an, so I used a 9/16-18NF tap on the inlet/outlet of the rails. There is supposed to be a grove machined for the oring AN fittings, I didn’t want to pay $300 for that so I just JB welded the fittings on. That is ghetto but it works well. The last step was to make a bracket to mount the rail to the TB, unfortunately the 06-07 TB’s only have one mounting boss per TB, so the mounting bracket has to be perfect or a car-b-que can result. When everything was done, I cleaned the rails up on my drill press using scotch pads, the result was a nice brushed finish.

Overall impression:

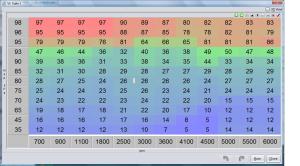

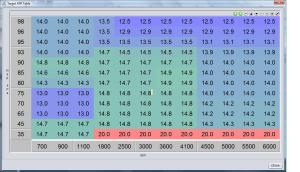

The longer intake run and the bigger bore creates a sexy growl when I’m on it. I cruise and idle with more vacuum now, so much so I re-indexed all my maps to take advantage of it. I haven’t taken it on any big trips yet but I expect the same or better mileage. I do have a lot smoother midrange and did not lose any throttle response. The verdict so far is this version is all win. I have a long trip in another week of so, I’ll use my GPS to try and get a accurate mpg.

Here is a fun little video, that’s about 20 minutes of tuning http://www.youtube.com/watch?v=Mp4p3V3jKoA

This blog post is all about the present. I’m going to list averything that I did to my type 4 2L, all the details of my megasquirt/ign setup and where I am at with this car. Bear in mind I bought the car just 9 months ago and it was just a shell of a notch and a truck load of parts and some blood, sweat, and tears plus lots of cash to get it where it is. The funny thing is i have no interior and need paint still, both of which are big dollar deals. Without further adue-

This blog post is all about the present. I’m going to list averything that I did to my type 4 2L, all the details of my megasquirt/ign setup and where I am at with this car. Bear in mind I bought the car just 9 months ago and it was just a shell of a notch and a truck load of parts and some blood, sweat, and tears plus lots of cash to get it where it is. The funny thing is i have no interior and need paint still, both of which are big dollar deals. Without further adue- The heart of this build is the type 4 motor. When i got the car it came with a 1600 dp and a weber progressive, not only did it have a garbo carb but it also had a rod knock. That was all I needed to start a type 4 build. I found a complete type 4 w/FI in cali, had it shipped to Tejas for a few bills. The funny thing is a local had a complete type 4, and he wanted $1200 for but he had no idea if it ran. I guess peeps think their stuff is made out of gold.

The heart of this build is the type 4 motor. When i got the car it came with a 1600 dp and a weber progressive, not only did it have a garbo carb but it also had a rod knock. That was all I needed to start a type 4 build. I found a complete type 4 w/FI in cali, had it shipped to Tejas for a few bills. The funny thing is a local had a complete type 4, and he wanted $1200 for but he had no idea if it ran. I guess peeps think their stuff is made out of gold.

Mega Squirt 1 v3.0 fuel/ign…giggity

Mega Squirt 1 v3.0 fuel/ign…giggity